Welcome to Kabelassistent

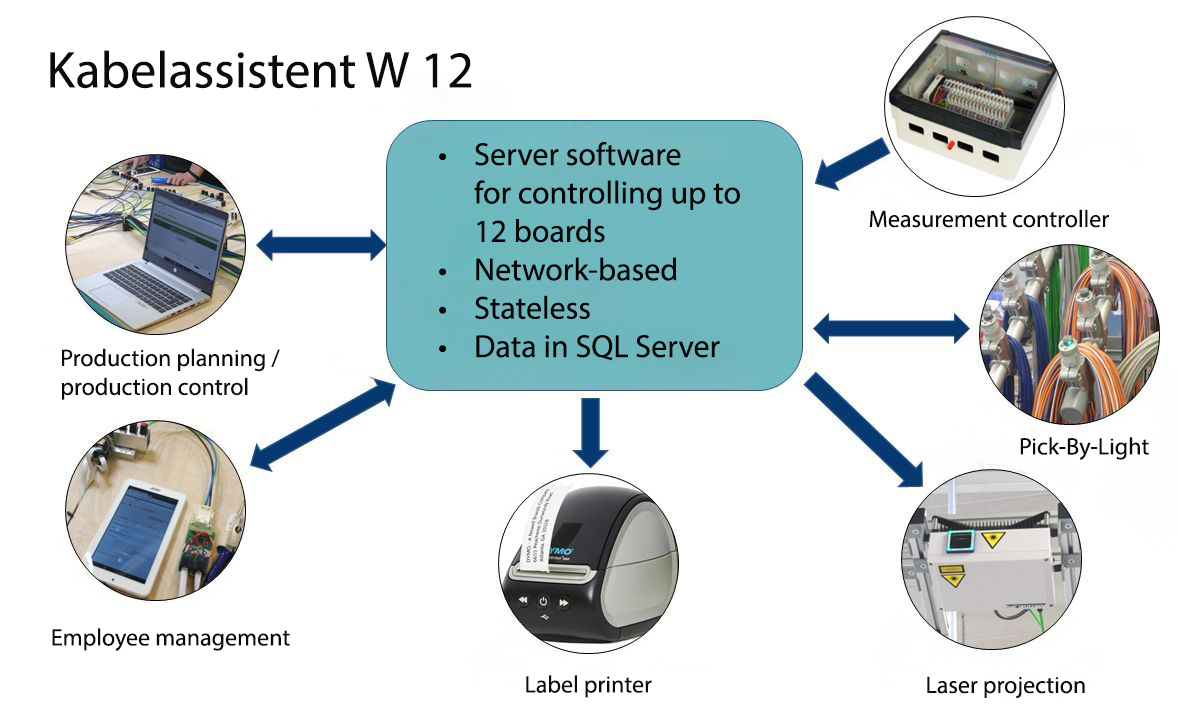

Kabelassistent W 12 is the software that controls all processes relating to assembly. It is completely network-oriented and can therefore be installed on a server away from the production area. One instance of Kabelassistent W 12 can operate up to 12 assembly boards.

Kabelassistent is web-based throughout. You can simply log in to Kabelassistent from any computer using a browser. Kabelassistent informs your employees with tablets on the assembly board. For large assembly boards, you can also make several tablets available on one board. All tablets that you have logged on to a board display the same information and the employees can operate Kabelassistent on an equal footing.

Kabelassistent receives the results of the continuity measurements from the measurement controller via a network connection. If there are no network connections in the production area or if you need flexibility when setting up the Kabelporter, the connection also works via WLAN.

Kabelassistent usually communicates with the Vario Trolley strand trolley via WLAN.

The laser projectors for assembly path projection require one Windows control computer per Kabelporter for the LaserCAM software. This program calculates the positions and rotations of the deflection mirrors from the coordinates of the waypoints. The connection between Kabelassistent and the control computer as well as between the control computer and the laser projector are normal network connections according to IP protocol. System administrators like to install the server for Kabelassistent and the PCs for the laser projectors as virtual machines on a shared hardware.

The label printers for type plates are managed by the Windows server on which Kabelassistent is installed. As a rule, these are also network printers.

Kabelassistent stores all data, both the article data and production planning data of the wire harnesses as well as the data of the assembly boards and all movement data, in a database on a Microsoft SQL server. This database also contains the data from Kabelassistent installations at other locations.

The entire server with the Kabelassistent W 12 installation is stateless, i.e. it has not saved anything itself. You can create new servers for the same or other locations by simply copying them. All you have to do is enter a new Windows Server license.

Cutting – cutting lists on the tablet, pick-by-light on the Vario Trolley.

Crimping – crimping lists on the tablet, pick-by-light on the Vario Trolley.

Pre-pinning – work lists in several steps on the tablet, pick-by-light for removing and hanging on the Vario Trolley.

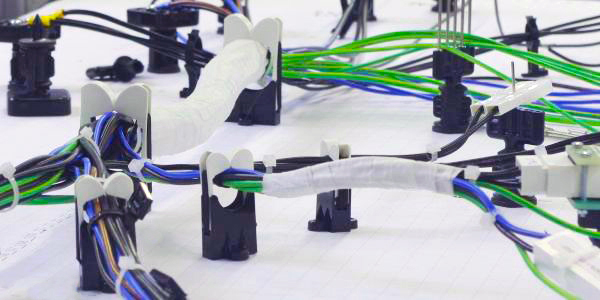

Assembly – assembly lists, work progress, error messages and connector images on the tablet, pick-by-light on the Vario Trolley, assembly path projection with feedback of the passage measurement on the assembly board.

Final work – list and confirmation on the tablet, position projection on the assembly board.

Label printing – You can freely design the labels with a free report generator. They can contain a serial number.

Display on tablet – display on one or more tablet PCs in parallel on the assembly board.

Continuity measurement – display in fractions of a second whether OK or error message with suggestion for correct connection.

Pick-By-Light on the Vario Trolley – removal of the strands with Pick-By-Light from the Vario Trolley according to the pick plan set by the supervisor.

Install-By-Light – projection of the installation paths of up to nine individual strands at the same time and the common path of pre-inserted strands with laser projector.

Connect-By-Light – feedback of the continuity measurement with brightness and color of the projection line in fractions of a second.

Finishing work – list of finishing work with laser projection of the positions of clips, cable ties or bandages, for example.

Label printing – once all the finishing work has been completed, employees print the label from the tablet.

List of strands to be laid – display of source and destination, color and cross-section.

List of finished strands - display of source and destination, color and cross-section.

Work progress – bar with total number and completed.

Pick plans – contains location, table, batch size, production status, created date, finished date.

Pick plan – sequence of strands, assemble individually or in groups. Determine whether all strands within the groups must be assembled at the same time or whether they can be freely selected by the employees.

List of work orders – adaptation of the pick-by-light to the skills of the employees with differentiated plans.

Vario Trolley – assignment of free vario trolleys to the work order.

Pick plan – selection of the pick plan for laying with pick-by-light or switching off the pick-by-light for free assembly.

Parking an operating order – interrupting the production of a lot.

List of completed wire harnesses – contains serial number, time of start, end of installation, label printing and completion.

Export of the list of finished wire harnesses – creates the list as an Excel file or .pdf.

Item list – designations and template for labels.

Assembly plans – connector and pin designations, photos of the position on the assembly board, the contact and the mating connector, strand color, cross-section.

Import of assembly plans – upload an Excel file.

Import of photos – photos for position on the assembly board, contact, connector face as a series import.

Import of laying lines – import of all lines of a wire harness from the teach-in program of the laser projector for individual lists and common paths of pre-plugged bundles.

Wiring list – connection between pins of mating connectors and measuring channels.

Switching Duplex measurement Simplex measurement – no difference in measurement channels between input and output or at least one output and one input per connection.

Measure wiring – practical assistant for creating the wiring list from the existing wiring by tapping with a test probe.

Email: info@kabelassistent.eu

Tel.: ++49 / 76 35 / 82 716 50

Fax: ++49 / 76 35 / 82 716 20

It is generally possible to use our website without providing personal data.